In the world of belts, two common types are the cogged belt and the V belt. Each type has its own unique features and advantages, making them suitable for different applications.After reading the following article, I believe you will have a deeper understanding

Definition and Structure

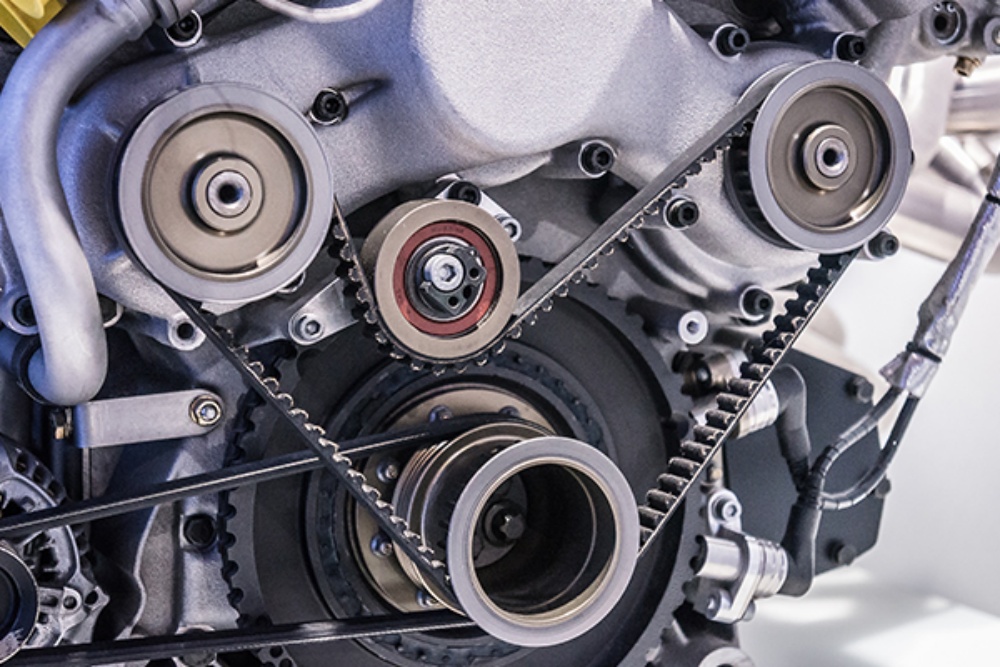

A cogged belt is a belt that uses cogs or teeth on its inner surface to transmit power. These cogs engage with a corresponding cogged pulley to create a mechanical advantage and transmit torque. The cogged belt is usually made from rubber or plastic and has a solid cross-section.

In contrast, a V belt is a belt that has a V-shaped cross-section. It is designed to fit into a correspondingly shaped groove in a V-belt pulley. The V belt is usually made from rubber or plastic and provides a flexible and efficient means of power transmission.

Performance Characteristics

Cogged belts are known for their high load-bearing capacity and are suitable for transmitting high torque. They offer good wear resistance and are typically used in heavy-duty applications such as industrial motors, pumps, and fans. However, cogged belts generate more noise during operation due to the engagement of cogs with the pulley.

V belts, on the other hand, have a smooth inner surface that reduces noise and friction. They are typically used in quieter applications such as household appliances, automobiles, and agricultural machinery. V belts also have good shock resistance, making them suitable for environments with frequent starts and stops.

Installation and Maintenance

Installing cogged belts requires more precision compared to V belts. The cogged belt must be aligned with the cogged pulley to ensure proper engagement and power transmission. Additionally, cogged belts may require more initial tension to ensure proper operation, as compared to V belts.

V belts, on the other hand, are easier to install due to their flexible nature. They can be installed with minimal tension, as they are designed to expand and contract when fitted around the pulley. This makes V belts ideal for applications where space is limited or access is difficult.

Cost Considerations

The cost of cogged belts and V belts varies depending on material, size, and manufacturer. In general, cogged belts tend to be more expensive than V belts due to their complex structure and precision manufacturing requirements. V belts, being simpler in design, are usually less expensive and more widely available.

Environmental Impact

Both cogged belts and V belts are made from non-renewable resources, such as rubber and plastic. However, cogged belts may require more material to achieve the same level of strength and durability compared to V belts. This may result in higher material waste and environmental impact during production.

Cogged Belt vs. V Belt

When choosing between a cogged belt and a V belt, it is important to consider your specific application requirements. If high torque transmission and load-bearing capacity are essential, cogged belts may be a better choice. However, if noise reduction, ease of installation, and cost-efficiency are important factors, V belts may be a more suitable option. Additionally, both belts have their own environmental impact considerations that should be taken into account during selection.

More:Precision and Performance: The Role of V-Pulley in Machinery Operations

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]