Custom Gears: Where Precision Meets the Unique Demands of Your Industry

In the intricate world of machinery and power transmission, there is no “one-size-fits-all” solution. Industries span a vast spectrum, each with its own set of demands, challenges, and intricacies. This is where custom gears come into play, bridging the gap between standardization and tailor-made precision.

At Oris, we understand that off-the-shelf gears might not always suffice, especially when industries demand precision, efficiency, and reliability. This realization has led us to specialize in crafting custom gears that are perfectly aligned with the unique needs of your industry.

The Art of Customization

The essence of custom gears lies in the art of customization. It’s about engineering gears that seamlessly integrate into your specific machinery, ensuring optimal functionality and longevity. Here’s how we achieve it:

- 1. Precision Engineering: Our journey towards crafting custom gears starts with a deep understanding of your industry’s requirements. We analyze the nuances of your machinery, from torque and speed to load capacity and operational conditions. This meticulous examination allows us to engineer gears with precision, tailored to your exact specifications.

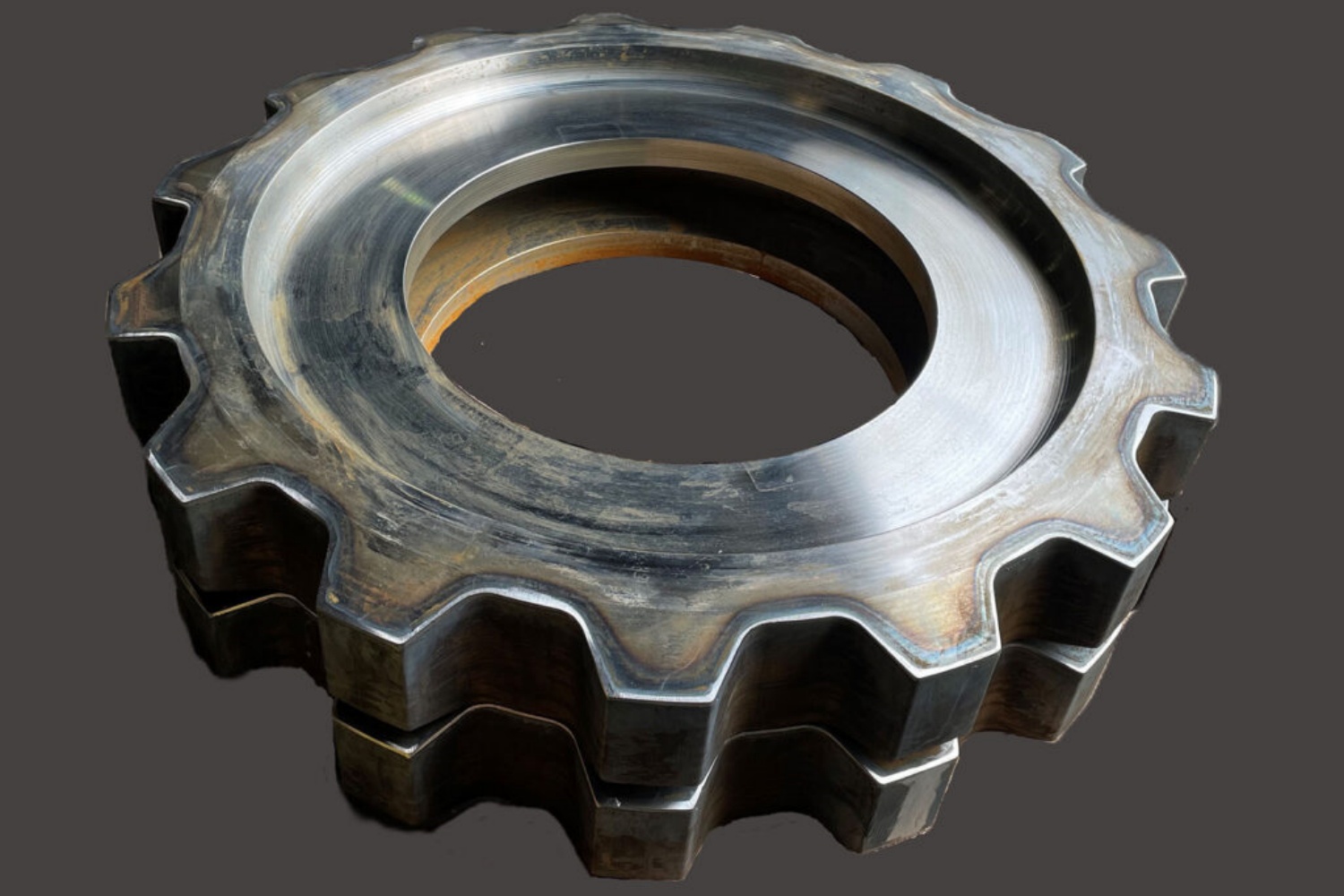

- 2. Material Selection: Different industries require different material properties for their gears. Whether it’s the durability of steel for heavy machinery or the lightweight versatility of aluminum for specialized applications, we choose materials that align with your industry’s demands.

- 3. Tooth Profiles: The tooth profile of a gear can significantly impact its performance. We carefully design tooth profiles that optimize power transmission, minimize wear, and reduce noise levels, ensuring seamless operation within your machinery.

- 4. Heat Treatment and Coatings: To enhance durability and reduce maintenance needs, we apply heat treatment and coatings tailored to your industry’s operational environment. This ensures that our custom gears can withstand the harshest conditions and remain resilient over time.

Industry Expertise

One of the key strengths of Oris is our deep industry expertise. We have worked with a diverse range of sectors, including but not limited to:

- Manufacturing: Precision and reliability are paramount in manufacturing processes. Our custom gears play a crucial role in ensuring smooth operations, from conveyor systems to automated machinery.

- Agriculture: In the agricultural sector, where heavy loads and outdoor conditions are the norm, our custom gears drive efficiency in tractors, harvesters, and other farm equipment.

- Automotive: Precision gears are the backbone of automotive transmissions. We cater to this industry’s need for high-performance, low-noise gears that guarantee a smooth ride.

- Aviation: The aviation industry relies on gears for everything from landing gear systems to engine components. Our custom gears meet the stringent standards of this highly regulated sector.

- Energy: In the energy sector, gears are pivotal in the operation of turbines, generators, and more. Our customized solutions ensure the seamless generation and distribution of power.

The Value of Customization

Investing in custom gears is an investment in the long-term efficiency and reliability of your machinery. Here’s the value they bring to your industry:

- Enhanced Performance: Custom gears are designed to excel in their intended applications, resulting in improved performance, reduced energy consumption, and increased productivity.

- Reduced Downtime: Gears that precisely fit your machinery experience less wear and tear, translating into fewer breakdowns and reduced downtime.

- Cost-Efficiency: While custom gears might have slightly higher upfront costs, their longevity and operational efficiency result in substantial long-term cost savings.

- Industry Compliance: Many industries have specific regulations and standards that machinery must adhere to. Our custom gears are designed to meet these requirements, ensuring compliance and peace of mind.

Custom gears from Oris are not just components; they are tailored solutions engineered to meet the unique demands of your industry. With precision engineering, material selection, and a deep understanding of your sector’s intricacies, we stand as your reliable partner in driving efficiency, reliability, and performance in your machinery. When standard gears fall short, custom gears from Oris rise to the challenge, ensuring your industry’s success, one gear at a time.

CONTINUE READING

Related Posts

In the realm of mechanical design and engineering, the choice between custom and standard gear sets is pivotal. This decision […]

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]