In today’s industrialized world, the role of sprockets goes beyond their functional significance. They are not just simple components of machines; they are the driving force behind the smooth operation of various industrial systems. However, traditional sprockets often lack the adaptability and efficiency required in modern industrial settings. This gap is being bridged by custom sprockets, which merge artisanal craftsmanship with industrial need.

Precision Engineering and Skilled Craftsmanship in Custom Sprocket Production

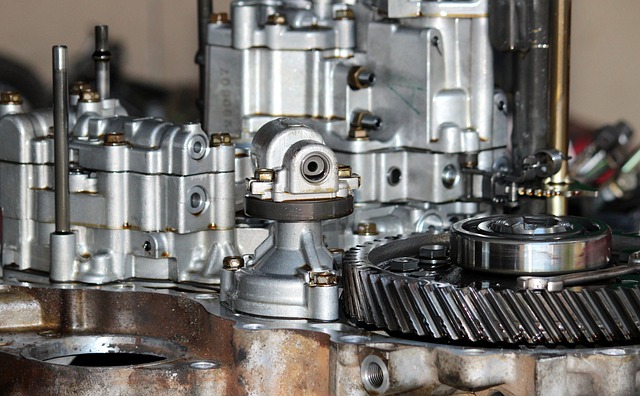

Custom sprockets are designed to meet specific requirements and overcome the limitations of traditional sprockets. They are tailored to fit unique applications, ensuring optimal performance and efficiency. The manufacturing process of custom sprockets involves meticulous planning, precision engineering, and skilled craftsmanship.

Addressing Industrial Needs with Custom-Tailored Sprockets

Artisanal craftsmanship is at the heart of custom sprocket design and production. Skilled artisans and engineers collaborate to create these precision components, utilizing traditional techniques and modern technologies. This combination allows for the creation of sprockets with unique designs, improved durability, and enhanced performance characteristics.

Custom sprockets are designed to address specific industrial needs. They are tailored to fit unique applications, such as conveyor systems, material handling equipment, or power transmission systems. By understanding the specific requirements of each application, custom sprockets can be designed to handle varying loads, reduce power losses, and improve operational efficiency.

The Versatility of Custom Sprockets in Today’s Industrial Landscape

The adaptability of custom sprockets is a key advantage in today’s rapidly evolving industrial landscape. They can be designed to fit a wide range of shaft configurations, materials, and load conditions, making them highly versatile components. This adaptability not only reduces the need for multiple sprockets but also ensures that each sprocket is optimized for its specific application.

Enhanced Durability and Reduced Maintenance with Custom Sprockets

Custom sprockets also offer improved durability compared to traditional sprockets. The use of high-quality materials and advanced manufacturing processes ensures that these components can withstand the rigors of industrial environments. The result is a sprocket that lasts longer, requires less maintenance, and performs consistently over its lifespan.

Driving Industrial Efficiency with Custom Sprockets

The impact of custom sprockets on industrial efficiency cannot be understated. By improving the efficiency of power transmission and reducing power losses, custom sprockets significantly enhance production output. They enable machinery to operate at optimal levels, ensuring that the desired output is achieved with minimal energy losses. This efficiency not only reduces operational costs but also improves productivity, leading to overall cost savings and increased profitability.

The Rising Popularity of Custom Sprockets in Various Industries

Custom sprockets are becoming increasingly popular in various industries due to their adaptability, durability, and performance advantages. From manufacturing to mining, transportation to energy production, the role of custom sprockets is becoming increasingly significant. As the demand for efficient, reliable, and sustainable industrial operations continues to grow, the use of custom sprockets will likely expand further.

The Future of Custom Sprockets in Industrial Operations

Custom sprockets are a testament to the power of merging artisanal craftsmanship with industrial need. They offer a unique blend of precision engineering, skilled craftsmanship, and adaptability to meet the demands of modern industrial applications. As the industrial landscape continues to evolve, custom sprockets will remain at the forefront, driving innovation and efficiency in industrial operations.

More: Reliable and Durable: Oris’ Industrial Chain Sprockets for All Applications

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]