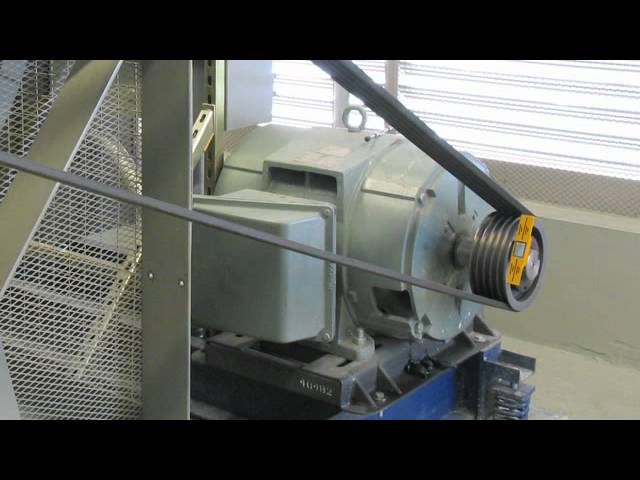

Installing or removing a V-belt pulley on an AC motor can be a little tricky and requires some special tools and techniques to do it properly.

Here are the general steps for removing a V-pulley from an AC motor:

- Disconnect the power supply: Before starting the process, ensure that the power supply to the motor is turned off and locked out to prevent accidental start-up.

- Remove the belt: The V-pulley is held in place by the belt that is wrapped around it. Use a wrench or a ratchet to release the tension on the belt tensioner, and slide the belt off the pulley.

- Remove the retaining bolts: Most V-pulleys are held in place by one or more retaining bolts that attach them to the motor shaft. Use a socket wrench or a spanner to remove the retaining bolts.

- Use a pulley puller: A pulley puller is a tool that is specifically designed to remove V-pulleys from motor shafts. It consists of a set of jaws that grip the pulley and a central screw that applies pressure to remove the pulley from the shaft. Attach the pulley puller to the pulley, and tighten the central screw until the pulley slides off the motor shaft.

- Clean the shaft: Once the pulley is removed, clean the motor shaft thoroughly to remove any debris, dirt or rust that may have accumulated. This will help ensure a proper fit for the new pulley.

- Install the new pulley: To install the new pulley, reverse the steps used for removing the old one. Ensure that the pulley is properly aligned with the motor shaft, and tighten the retaining bolts securely. Install the belt and adjust the tensioner to the manufacturer’s specifications.

Here are the general steps for installing a V-pulley on an AC motor:

- Choose the right pulley: Before installing a new V-pulley on an AC motor, ensure that you have selected the correct pulley for the motor. Check the manufacturer’s specifications for the correct size, bore diameter, and number of grooves.

- Clean the shaft: Ensure that the motor shaft is clean and free from debris, rust, and other contaminants. Use a clean rag and a suitable cleaning solvent to wipe the shaft and remove any residue.

- Inspect the keyway: Check the keyway on the motor shaft to ensure that it is clean and free from burrs or damage. The keyway is a small slot cut into the shaft that the pulley key fits into to prevent the pulley from slipping on the shaft.

- Insert the key: If the pulley has a keyway, insert the key into the keyway on the motor shaft. The key should fit snugly into the keyway and extend slightly beyond the width of the shaft.

- Slide the pulley onto the shaft: Align the pulley with the motor shaft and slide it onto the shaft until it is snug against the motor housing. Ensure that the pulley is seated properly on the shaft, and the keyway on the pulley aligns with the key on the motor shaft.

- Tighten the retaining bolts: Most V-pulleys are held in place by one or more retaining bolts that attach them to the motor shaft. Use a socket wrench or a spanner to tighten the retaining bolts securely. Tighten the bolts in a star pattern to ensure that the pulley is evenly tightened onto the motor shaft.

- Install the belt: Once the pulley is securely attached to the motor shaft, install the belt onto the pulley and adjust the tensioner to the manufacturer’s specifications.

It’s important to note that the specific process for installing a V-pulley on an AC motor may vary depending on the make and model of the motor, as well as the type of pulley used. It’s always recommended to consult the manufacturer’s instructions or a professional mechanic for guidance on proper pulley installation techniques.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]