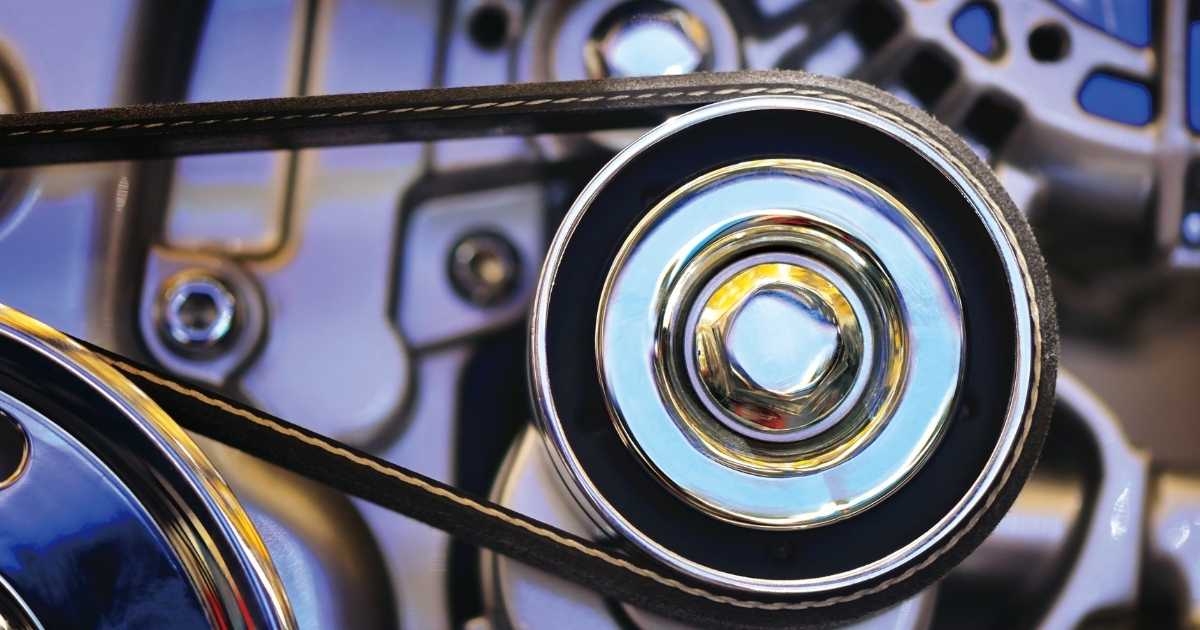

V-belts are a common power transmission belt used in various industrial applications. To ensure efficient and reliable operation, it is essential to measure the pulleys accurately before installing the V-belt.

Understanding the Pulleys

Pulleys are the components that support the V-belt and transmit power from one machine to another. They come in various sizes and shapes depending on the application. The two main types of pulleys are fixed pulleys and adjustable pulleys. Fixed pulleys have a fixed groove width, while adjustable pulleys have a movable groove width that allows for easy installation and adjustment of the belt.

Measuring the Pulleys

Measuring the pulleys is crucial to determine the correct size of the V-belt required. Here are the steps to measure the pulleys accurately:

Step 1: Identify the type of pulley

First, identify the type of pulley you have. Fixed pulleys have a fixed groove width, while adjustable pulleys have a movable groove width. Adjustable pulleys are more common and offer better versatility as they can be adjusted to different belt sizes.

Step 2: Measure the grove width

Using a measuring tape or a vernier caliper, measure the grove width of the pulley. The grove width is the distance between the two sides of the pulley groove. This measurement will determine the width of the V-belt required to fit onto the pulley.

Step 3: Measure the outside diameter

Next, measure the outside diameter of the pulley using a measuring tape or vernier caliper. This measurement will help you select the correct V-belt size that matches the pulley diameter.

Step 4: Consider other factors

While measuring, also consider other factors that may affect the selection of V-belt size, such as the operating speed of the machinery, load requirements, and environmental conditions. These factors will help you choose the appropriate belt material and construction for your application.

Selecting the Correct V-Belt Size

Based on the measured grove width and outside diameter of the pulleys, select the correct V-belt size that matches the dimensions. Check the manufacturer’s recommendations or consult a professional to ensure you select the appropriate belt size for your application. It is essential to use V-belts that are compatible with your machinery and provide efficient power transmission.

Installing the V-Belt on the Pulleys

Once you have selected the correct V-belt size, it’s time to install it on the pulleys. Follow these steps:

Step 1: Clean the pulley surfaces

Clean the pulley surfaces thoroughly to remove any dirt, grease, or debris that may affect the installation of the V-belt. Use a clean cloth or abrasive cleaner to ensure a clean and smooth surface.

Step 2: Position the V-belt on the pulley

Carefully position the V-belt on the pulley so that it fits into the groove comfortably without any sagging or stretching. Ensure that the belt is aligned correctly and there are no twists or folds in it.

Step 3: Secure the V-belt in place

Once the V-belt is positioned correctly on the pulley, secure it in place using suitable fasteners or tensioning devices provided by the manufacturer. Tighten the fasteners gradually until you achieve the desired belt tension, ensuring that there is no slack in the belt while it is still loose on the pulley.

More: The SPB V Belt Pulleys: Pioneering Industrial Efficiency with Shanghai Oris

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]