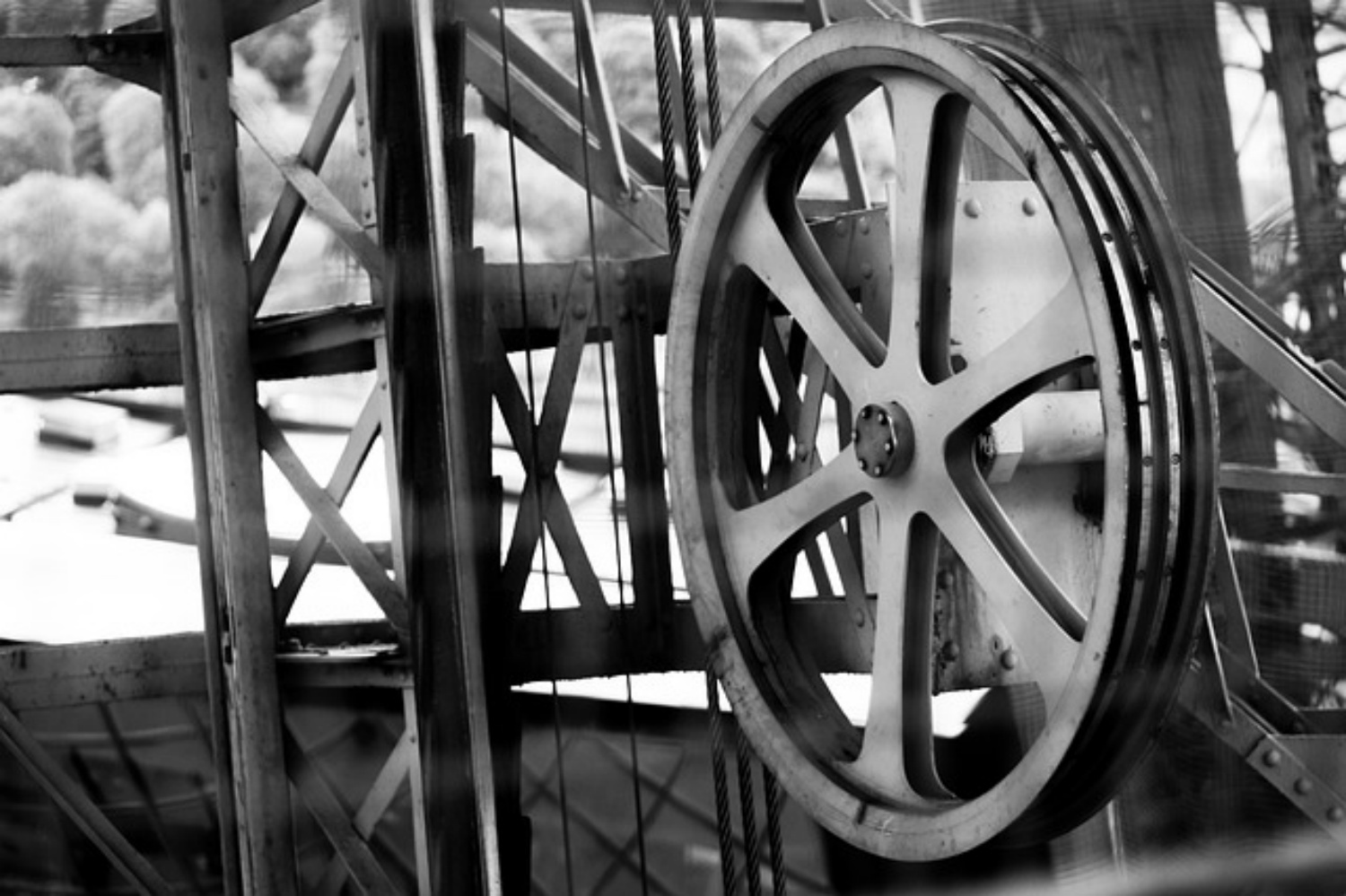

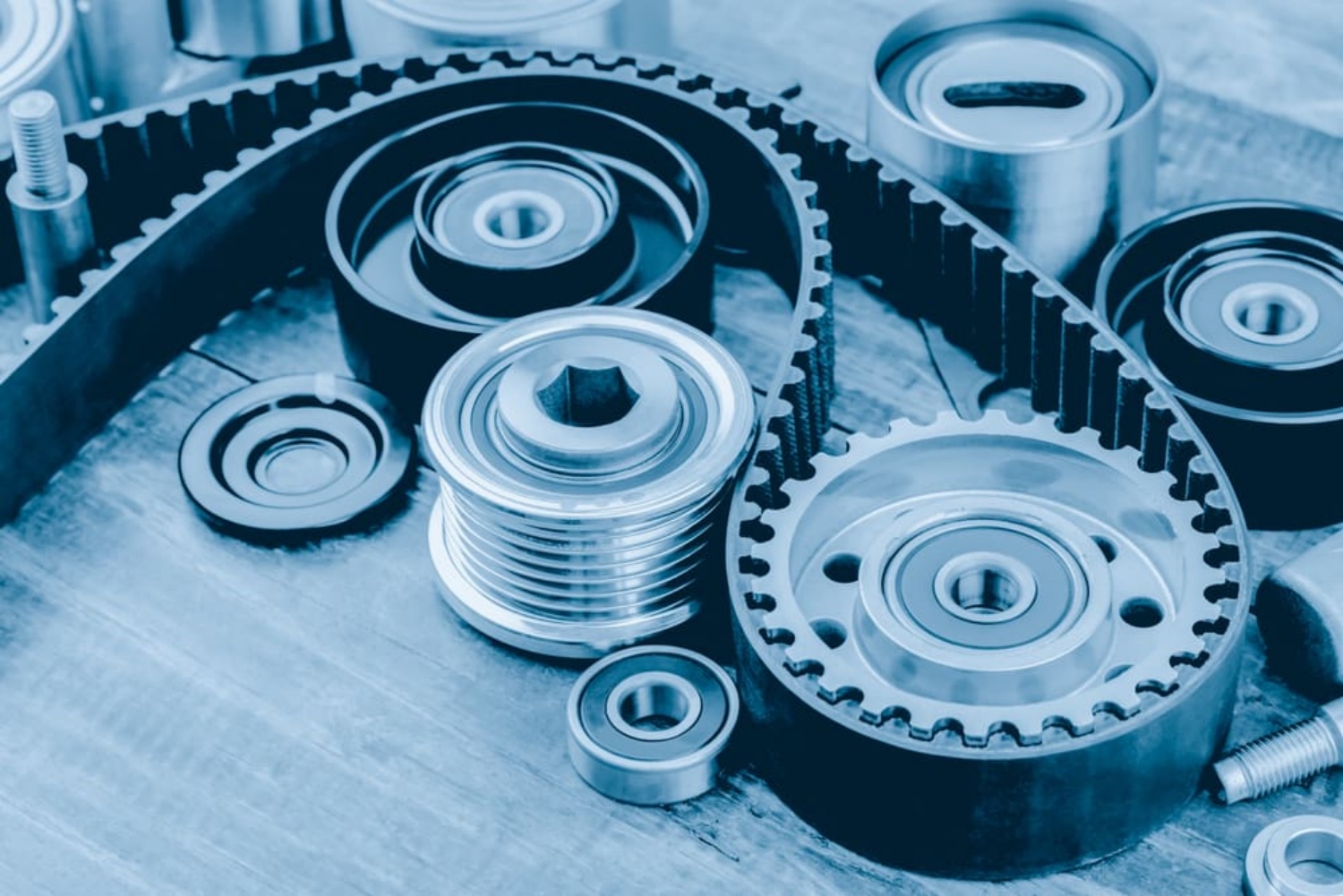

Pulleys play a crucial role in various industries, facilitating the transfer of power and motion in mechanical systems. However, the environment in which pulleys operate can significantly impact their performance and longevity. Factors such as temperature, humidity, dust, chemicals, and vibrations can affect the efficiency, durability, and overall effectiveness of pulleys. In this article, we will explore the impact of the environment on pulleys and discuss key factors to consider for maintaining optimal performance and extending their service life.

Temperature and Thermal Effects:

Extreme temperatures can have a significant impact on pulleys. High temperatures can cause thermal expansion, leading to misalignment and increased wear on the pulley components. In contrast, low temperatures can cause the lubricants to thicken, affecting the smooth operation of the pulleys. It is crucial to select pulley materials that can withstand the temperature ranges of the operating environment. Lubrication and insulation techniques can also help mitigate the adverse effects of temperature fluctuations on pulleys.

Humidity and Moisture:

High humidity levels and exposure to moisture can lead to corrosion, rust, and degradation of pulley components. Pulleys in outdoor or humid environments, as well as those subjected to water spray or immersion, require proper sealing and corrosion-resistant materials. Regular inspection and maintenance, including cleaning and lubrication, are essential to prevent moisture-related issues and ensure the longevity of pulleys.

Dust and Particulate Contamination:

Dust, dirt, and particulate matter present in the operating environment can accumulate on pulley surfaces and in bearing systems. This can lead to increased friction, wear, and decreased efficiency. Regular cleaning and maintenance practices, such as using protective covers or enclosures, are necessary to prevent the ingress of contaminants and ensure smooth pulley operation. Choosing sealed or shielded bearings can also provide additional protection against dust intrusion.

Chemical Exposure:

Pulleys operating in environments with exposure to chemicals, solvents, or corrosive substances require careful material selection. Chemicals can degrade pulley materials, leading to cracking, deterioration, or weakening of the pulley structure. It is important to consider the compatibility of the pulley materials with the specific chemicals present in the environment. In some cases, coatings or surface treatments can be applied to enhance chemical resistance.

Vibration and Shock:

Excessive vibrations or shocks in the operating environment can impact pulley performance. Vibrations can cause misalignment, increased noise, and premature wear on pulley components. Proper alignment, mounting, and the use of vibration-damping materials can help minimize the effects of vibrations and shocks on pulleys. Additionally, selecting pulleys with reinforced construction or shock-absorbing properties can improve their resilience to dynamic loads.

Conclusion:

The environment in which pulleys operate has a significant impact on their performance, reliability, and lifespan. Temperature fluctuations, humidity, dust, chemicals, and vibrations can affect pulley efficiency, wear rates, and overall functionality. To ensure optimal performance and extend the service life of pulleys, it is crucial to consider the specific environmental factors and select pulleys with suitable materials, coatings, and protective measures. Regular maintenance, including cleaning, lubrication, and inspections, is essential to identify and address any environmental-related issues promptly. By understanding the impact of the environment on pulleys and taking proactive measures, industries can maximize the efficiency and longevity of their pulley systems.

CONTINUE READING

Related Posts

The agricultural sector has always been a cornerstone of human civilization, providing the necessary resources for survival and prosperity. As […]

Industrial pulleys are an integral part of the machinery that powers the modern world. From manufacturing plants to construction sites, […]

In the realm of mechanical engineering and design, the terms “pulley” and “sheave” often surface, leading to a mix of […]