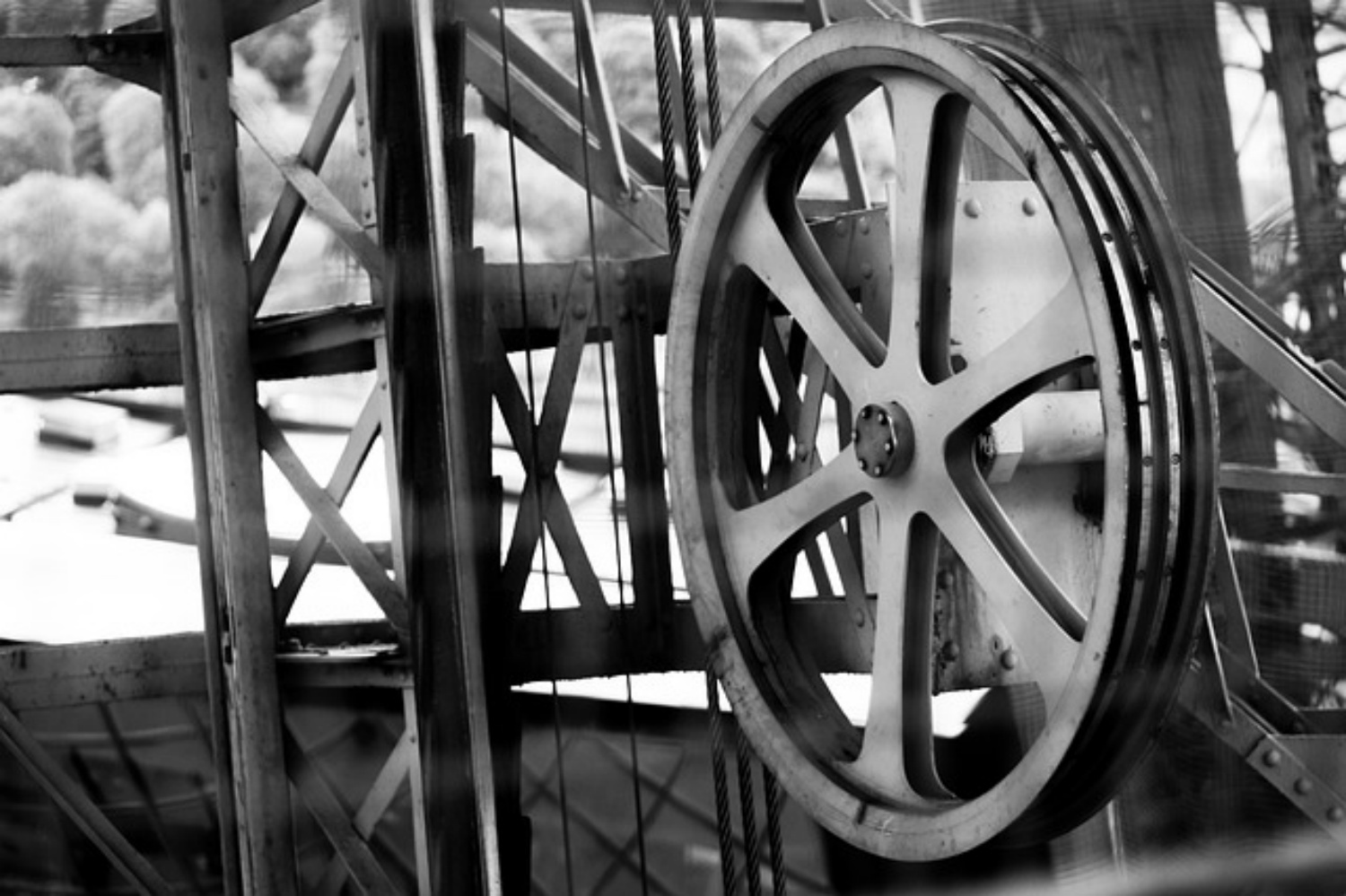

The advantages of the Pulley:

Pulley transmission runs smoothly with low noise and low vibration;

The structure of the pulley transmission is simple and easy to adjust;

The requirement for manufacturing and installation accuracy of pulleys during the transmission is not as strict as other meshing transmissions;

The belt pulley transmission has the function of overload protection;

There is a relatively large adjustment range of the center distance of the two shafts driven by the belt pulley.

The disadvantages of the Pulley transmission:

There is elastic sliding and skidding during the pulley transmission, as well as the transmission efficiency is low and the accurate transmission ratio cannot be maintained;

The outline size and the pressure on the shaft are larger than the meshing drive when the belt pulley drives the same large circumferential force;

The life span of the pulley drive belt is relatively short.

The diameter of the pulleys of various mechanical equipment is designed according to the reduction ratio, the working speed and the speed of the motor.

Working speed / motor speed = driving wheel diameter / driven wheel diameter * 0.98 (slip coefficient),

The operating speed is required to be no higher than 40m/s if the steel is used as the material of the belt pulley, while the requirement would be no higher than 35m/s if cast iron is used. The conversion ratio of motor speed to pulley diameter, speed ratio = output speed: input speed = Load pulley pitch circle diameter: motor pulley pitch circle diameter.

The pitch circle diameter is the same as the reference diameter. Diameter -2h = pitch circle diameter, and h is the groove depth on the reference line.

The pulley pitch circle diameter is the theoretical diameter of the pulley pitch line position, which is a bit like the index circle diameter of a gear. It is generally represented by PD, and the outer circle is generally represented by OD.

SPZ:OD=PD+4;SPA:OD=PD+5.5;SPB:OD=PD+7;SPC:OD=PD+9.6

There is a difference in conversion formulas of various groove-shaped pitch circles and outer circles. Generally, it is easier to measure the outer circle of the pulley, and then calculate the pitch circle according to the formula. SPZ:OD=PD+4;SPA:OD=PD+5.5;SPB:OD=PD+7;SPC:OD=PD+9.6 .

The minimum outer diameter of the pulley of A or SPA is 80mm. The belt is prone to delamination and cracks at the bottom if it is smaller than this size and especially at high speed.

The size of the small wheel for SPZ belt is not less than 63mm would be fine. At the same time, please pay attention to the method and tension of the belt installation. It will slip easily if too small, and will damage the belt and bearings if too large.

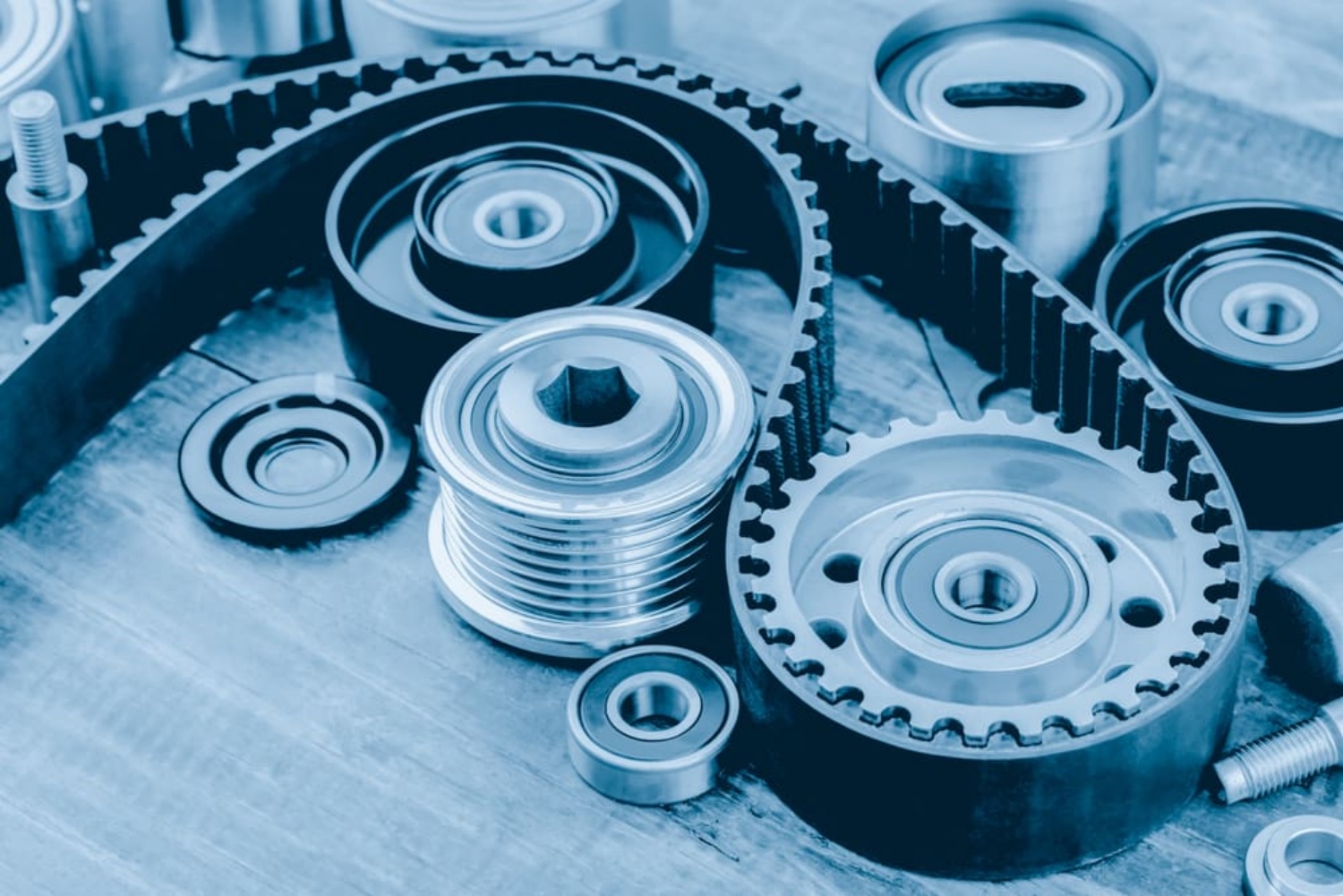

Pulley specifications

The specifications of the V-belt are divided by the size of the back width (top width) and height (thickness). Based on this, the national standard stipulates the O, A of the V-belt, B, C, D, E and many other models. Each model of the V-belt has different pitch widths, top widths and heights, so the pulley must be made into various grooves according to the shapes of the V-belts. The pulley model is decided by these different groove types: A-type pulley, B-type pulley, C-type pulley, and Z-type pulley.

CONTINUE READING

Related Posts

The agricultural sector has always been a cornerstone of human civilization, providing the necessary resources for survival and prosperity. As […]

Industrial pulleys are an integral part of the machinery that powers the modern world. From manufacturing plants to construction sites, […]

In the realm of mechanical engineering and design, the terms “pulley” and “sheave” often surface, leading to a mix of […]