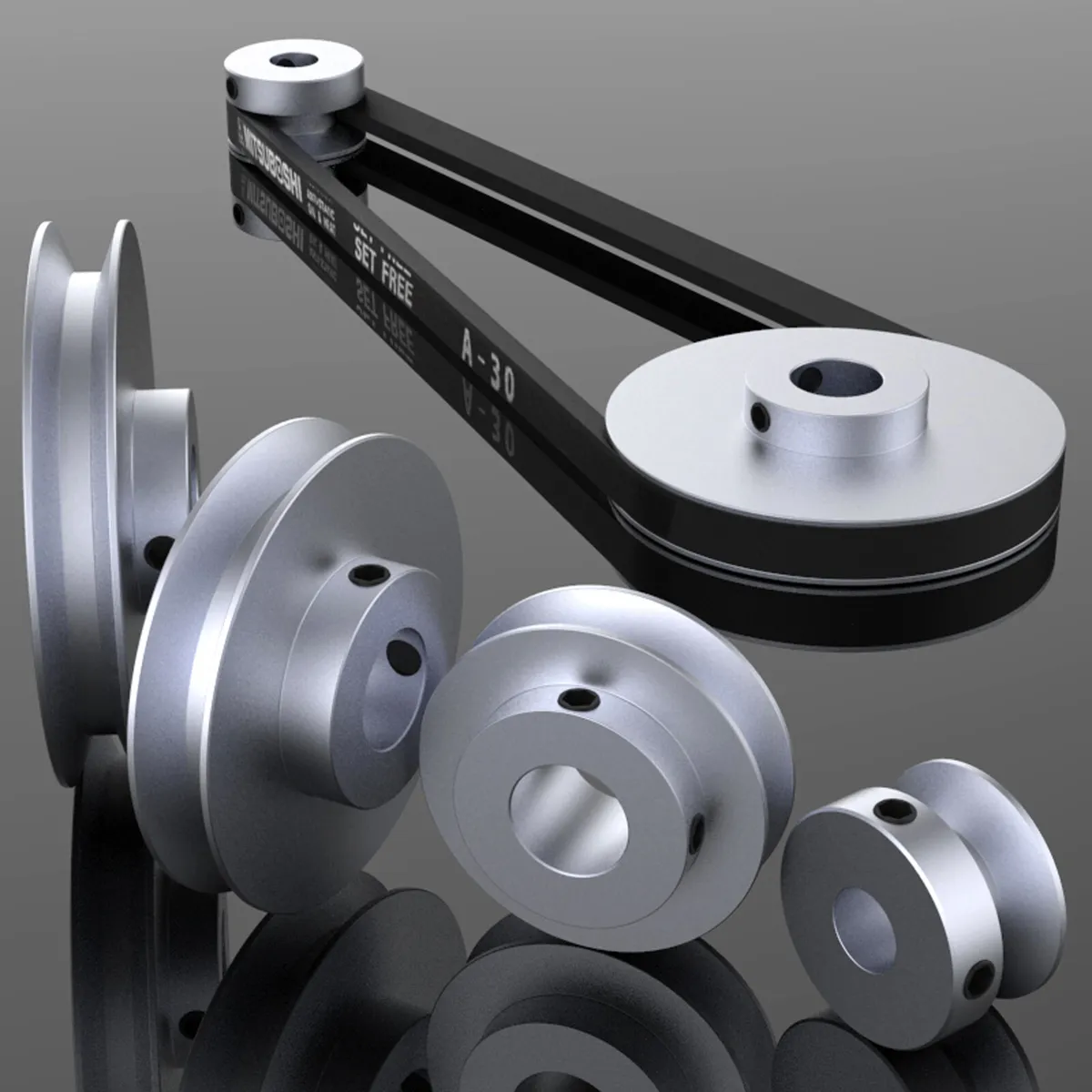

Vee belt pulleys have become an essential component in industrial applications due to their unique design and performance characteristics. The efficient transmission of power is critical in various industrial sectors, and the use of vee belt pulleys provides a reliable and cost-effective solution.

Efficient Power Transmission

Vee belt pulleys are designed for efficient power transmission, ensuring that the power loss during transmission is minimal. The unique V-shaped design of the belt allows it to engage with the pulley teeth, providing a secure and slip-free power transfer. This efficient power transmission is crucial in industrial applications where power loss can result in reduced productivity and increased energy costs.

Versatility

Vee belt pulleys are a versatile solution for various industrial applications. They can be used in a wide range of machinery and equipment, including conveyors, lifting systems, fans, pumps, and more. The ability to adapt to different machinery and equipment makes the vee belt pulley a go-to solution for many industrial applications.

Easy Installation and Maintenance

Vee belt pulleys are designed for easy installation and maintenance. The belt can be easily slipped onto the pulley, and the installation process requires minimal tools and expertise. Similarly, the maintenance of vee belt pulleys is straightforward, as they require minimal lubrication and have a long service life. The ease of installation and maintenance reduces downtime and saves costs associated with the replacement of belts or pulleys.

Durability and Reliability

Vee belt pulleys are made from high-quality materials that ensure their durability and reliability. The belts are typically made from rubber or polyurethane, while the pulleys are constructed from cast iron or steel. The combination of these materials ensures that the pulley system can withstand heavy loads and continuous use over long periods of time. The durability and reliability of vee belt pulleys also contribute to the overall efficiency and productivity of industrial systems.

Cost-Effective Solution

Vee belt pulleys offer a cost-effective solution for industrial applications. The initial cost of purchasing vee belt pulleys is often lower compared to other types of belts or drives. Additionally, their low maintenance requirements and long service life further reduce the overall cost of ownership. The cost-effectiveness of vee belt pulleys makes them a popular choice for various industrial applications where cost-efficiency is a top priority.

Compact Design

Vee belt pulleys have a compact design that allows them to fit into tight spaces and accommodate various industrial machinery and equipment. The compact design also makes it easy to integrate vee belt pulleys into existing systems without major modifications or redesigns. ThisCompact design of vee belt pulleys facilitates easy installation and integration into various industrial applications.

Quiet Operation

Vee belt pulleys are known for their quiet operation compared to other belt systems. The V-shaped design of the belt reduces noise generation during operation, making it ideal for applications where noise control is critical, such as in production environments or close-quartered workspaces. The quiet operation of vee belt pulleys helps to improve the working conditions and overall productivity.

The use of Vee belt Pulleys in industrial applications provides a range of benefits, including efficient power transmission, versatility, ease of installation and maintenance, durability and reliability, cost-effectiveness, compact design, and quiet operation. Their adaptability to different machinery and equipment makes them a go-to solution for various industrial applications, contributing to the overall efficiency and productivity of industrial systems.

More: Maintaining Efficiency: Proper Care for Your 1 Bore V Belt Pulley

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]