The world of machinery and manufacturing is intricate, where even the smallest part can have a significant impact on the overall output and efficiency of operations. One such critical component is the v belt pulley, and within this category, particularly the large v belt pulleys.

Shanghai Oris, one of China’s leading manufacturers of these essential components, brings to light their role, efficiency maximization, and future relevance in manufacturing.

Understand the Role of Large V Belt Pulleys in Modern Machinery

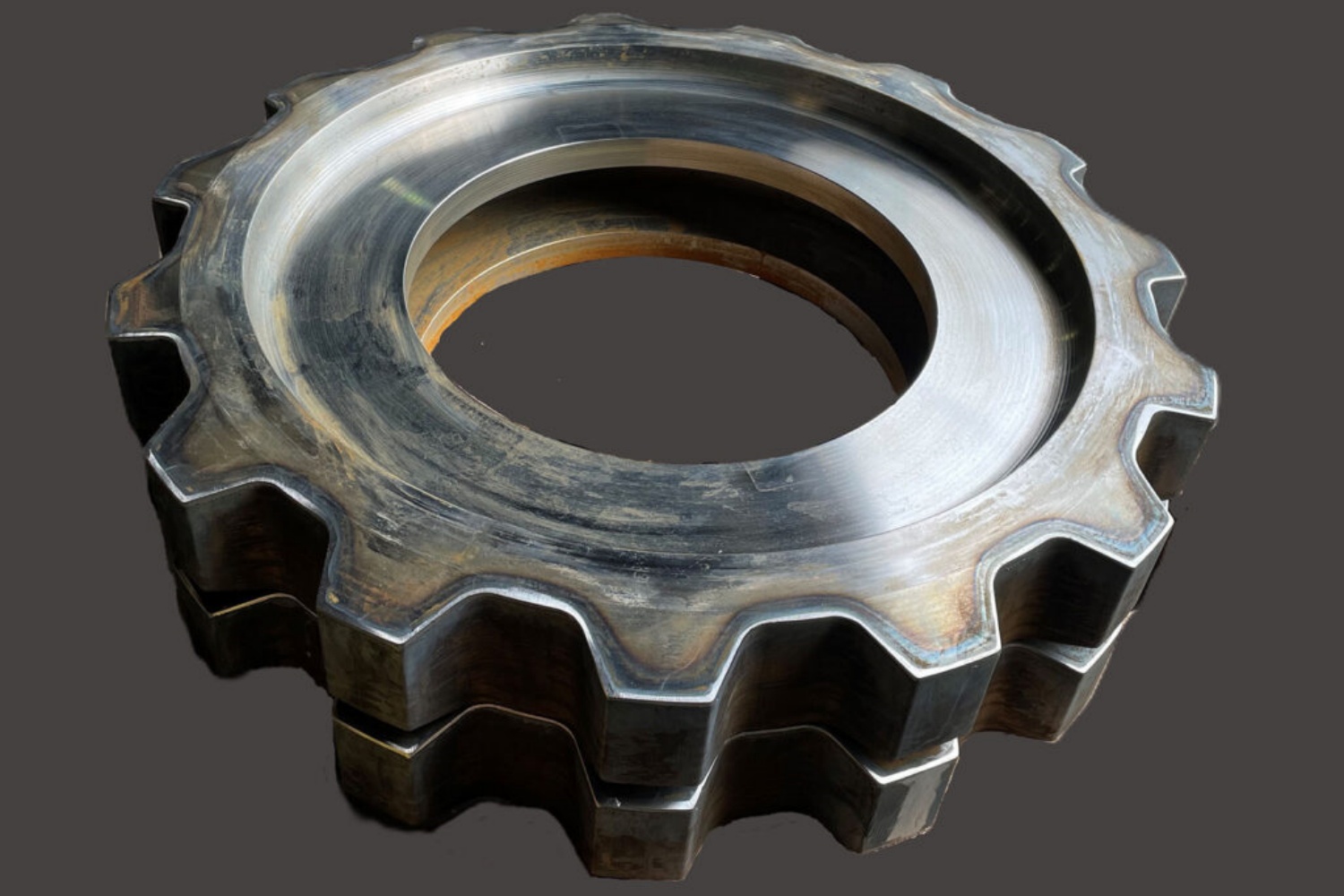

A v belt pulley is not just a wheel with a groove; it’s a precision-engineered tool that directly influences the performance of an array of machinery. The large v belt pulleys, being significantly larger in diameter, are designed to control speed variations and power transmissions in heavy-duty applications.

At Shanghai Oris, we’ve seen firsthand how large v belt pulleys can influence the effective operation of machinery. They are primarily responsible for transmitting torque from one part of the machine to another, enabling movements, controlling rotational speed, and synchronizing mechanical components. In essence, large v belt pulleys act as the connecting bridge between different mechanical parts, ensuring smooth and efficient operations.

Maximizing Efficiency with Large V Belt Pulleys

Efficiency is the name of the game in modern manufacturing. Any opportunity to reduce energy usage and increase output cannot be overlooked. Large v belt pulleys are one such opportunity.

By design, the large size of these pulleys provides more surface contact area with the belt, reducing slippage and improving the transfer of power between machine components. They enable slower and more controlled rotations, minimizing wear and tear and prolonging the lifespan of the machinery. The choice of pulley material also plays a part in maximizing efficiency – Shanghai Oris uses premium materials that balance durability and weight, ensuring optimal energy use and longevity.

Moreover, large v belt pulleys allow for a greater range of speed ratios, giving manufacturers more flexibility and control over their processes. By optimizing the size and configuration of these pulleys, we can fine-tune the operation of the machinery to maximize efficiency and productivity.

How Large V Belt Pulleys are Shaping the Future of Manufacturing

The advent of Industry 4.0 has led to an increased emphasis on automation, efficiency, and smart manufacturing. The humble v belt pulley, especially the large variant, is playing a crucial role in this transformation.

With their enhanced torque and power transmission capabilities, large v belt pulleys enable the operation of larger and more advanced machinery, facilitating automated and efficient manufacturing processes. As the industry moves towards greener production methods, the energy efficiency provided by these pulleys is also increasingly important.

Moreover, innovations in material science and engineering are leading to the development of even more robust and efficient pulleys. At Shanghai Oris, we are always on the forefront of these advancements, continuously improving our products to meet the evolving demands of the manufacturing sector.

The importance of large v belt pulleys in modern manufacturing cannot be overstated. They play a crucial role in machinery operation, help maximize efficiency, and are instrumental in shaping the future of the industry. At Shanghai Oris, we are committed to developing high-quality v belt pulleys that meet the demands of today and tomorrow.

CONTINUE READING

Related Posts

In the realm of mechanical design and engineering, the choice between custom and standard gear sets is pivotal. This decision […]

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]