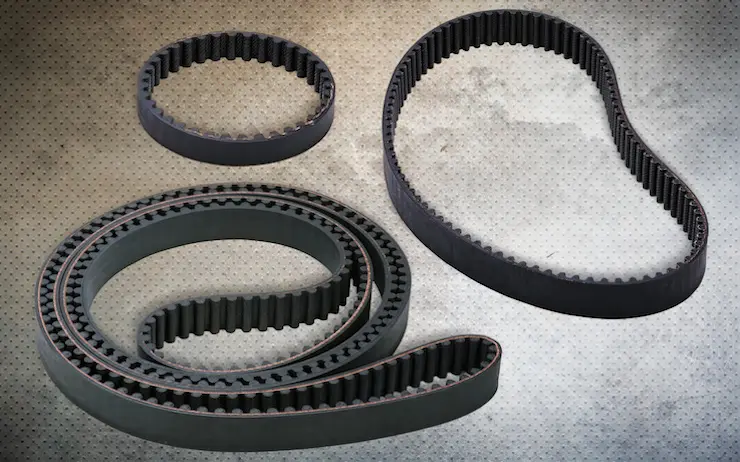

A v-belt pulley is a mechanical device used to transfer power between a motor and a machine. It is a type of pulley that uses a v-shaped belt to transmit torque and rotational power from one component to another. The 20 v belt pulley is a specific type of v-belt pulley that has unique characteristics and properties that make it a popular choice for many applications. In this article, we will explore the characteristics of 20 v belt pulleys and their benefits.

Size and Design

The 20 v belt pulley is typically larger than other v-belt pulleys, with a diameter of around 20 inches. The size of the pulley depends on the application and the amount of power that needs to be transferred. 20 v belt pulleys are designed to have a deeper groove than other v-belt pulleys, which allows them to transmit more power without slipping.

Material

20 v belt pulleys are usually made of cast iron or steel, which makes them strong and durable. The material used for the pulley depends on the application and the environment in which it will be used. For example, if the pulley is going to be used in a corrosive environment, stainless steel may be a better choice than cast iron.

Number of Grooves

The number of grooves in a v-belt pulley determines the number of belts that can be used to transmit power. 20 v belt pulleys usually have two or three grooves, which means they can be used with two or three v-belts. This allows them to transmit more power than a single-groove pulley.

Speed Ratio

The speed ratio of a v-belt pulley is the ratio between the speeds of the motor and the driven component. 20 v belt pulleys are designed to provide a specific speed ratio, which is determined by the number of grooves and the size of the pulley. This makes them suitable for applications that require a specific speed ratio, such as industrial machinery.

Taper Lock Bushing

Many 20 v belt pulleys come with a taper lock bushing, which is a device that allows the pulley to be easily mounted on a motor shaft. The taper lock bushing is designed to fit tightly on the shaft and lock the pulley in place. This makes it easy to install and remove the pulley when necessary.

Maintenance

Like all mechanical components, 20 v belt pulleys require regular maintenance to ensure they continue to function properly. Maintenance may include cleaning, lubrication, and inspection for wear and damage. Regular maintenance can help prolong the life of the pulley and prevent breakdowns and failures.

In conclusion, the 20 v belt pulley is a versatile and durable mechanical component that is widely used in many applications. Its unique design, size, and material make it suitable for transmitting large amounts of power without slipping. The number of grooves and speed ratio can be customized to meet the specific requirements of each application. The taper lock bushing makes it easy to install and remove the pulley, and regular maintenance can help prolong its lifespan.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]