V-pulley systems are critical components in power transmission, ensuring efficient belt-driven operation across various applications. However, like any mechanical system, V-pulley systems can encounter issues that impact their performance and reliability. Understanding common problems and their root causes is essential for effective troubleshooting. In this article, we will explore common issues that arise in V-pulley systems, including misalignment, belt slippage, excessive wear, and noise generation. By learning how to identify and address these problems, engineers and operators can mitigate downtime, extend the lifespan of V-pulley systems, and optimize their overall performance.

Misalignment :

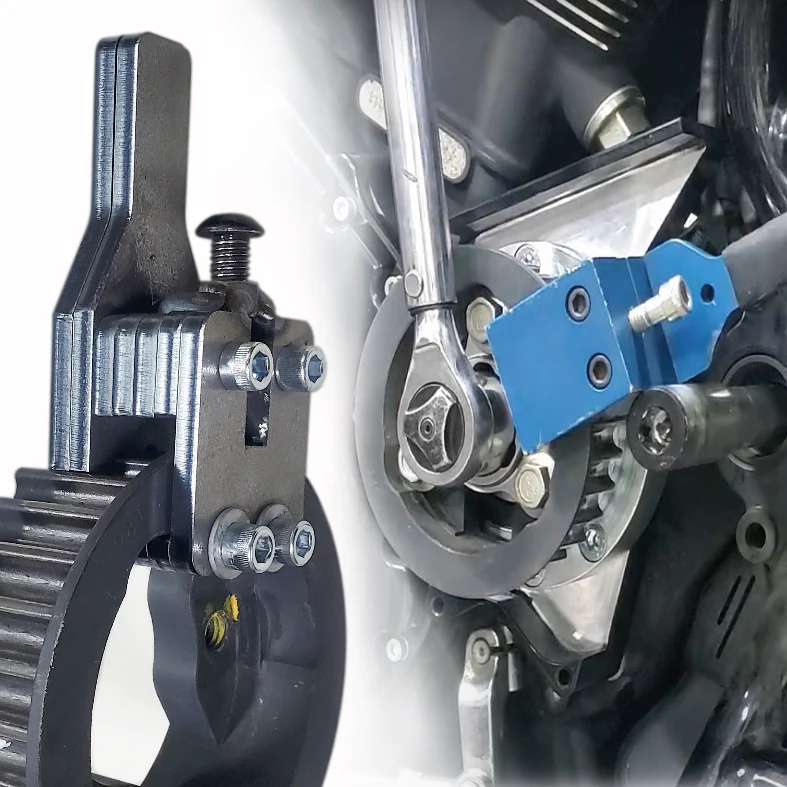

Misalignment occurs when the V-pulley and driven equipment are not properly aligned. This can result from improper installation, foundation settling, or vibration-induced movement. Misalignment leads to increased belt wear, reduced power transmission efficiency, and premature failure. To resolve misalignment, use alignment tools to realign the V-pulley and driven equipment, ensuring they are parallel and have the correct angular and axial alignment.

Belt Slippage :

Belt slippage occurs when the belt fails to maintain proper grip and slips on the V-pulley surface. It can be caused by insufficient belt tension, worn-out belts, contaminated pulley surfaces, or excessive loads. To address belt slippage, check and adjust the tension to the manufacturer’s recommendations, replace worn-out belts, clean pulley surfaces, and ensure the load does not exceed the belt’s capacity.

Excessive Wear :

Excessive wear on V-pulleys can lead to reduced performance and belt life. Factors contributing to wear include inadequate lubrication, abrasive contaminants, excessive belt tension, and misalignment. Regularly inspect the pulleys for signs of wear, such as groove deformation, rough surfaces, or excessive material loss. Proper lubrication, cleaning, and maintenance practices are crucial to minimize wear. If wear is severe, consider replacing the pulleys to avoid compromising system performance.

Noise Generation :

Unusual noises, such as squeaking, screeching, or rumbling, indicate potential issues in the V-pulley system. Noise can be caused by misalignment, belt slippage, worn-out belts, insufficient lubrication, or pulley imbalance. Identifying the root cause requires a systematic approach. Start by inspecting the alignment, tension, and condition of the belts. Lubricate the pulley bearings if necessary, and balance the pulleys if imbalance is detected. Addressing the underlying cause of noise will help restore smooth and quiet operation.

Overheating :

Overheating in V-pulley systems can be a result of excessive friction, inadequate lubrication, or high ambient temperatures. High temperatures can cause accelerated belt wear, belt degradation, and premature system failure. Ensure proper lubrication of bearings, reduce friction by adjusting belt tension, and provide adequate cooling mechanisms in high-temperature environments. Regularly monitor operating temperatures to identify any abnormal increases and take necessary corrective actions.

Conclusion :

Troubleshooting common issues in V-pulley systems is crucial to ensure optimal performance, reliability, and longevity. By effectively addressing misalignment, belt slippage, excessive wear, noise generation, and overheating, engineers and operators can minimize downtime, extend the life of V-pulley systems, and enhance power transmission efficiency. Regular inspections, maintenance practices, and adherence to manufacturer guidelines are essential in preventing and resolving problems. Implementing proactive troubleshooting measures will contribute to the smooth and efficient operation of V-pulley systems, maximizing their performance in diverse applications.

CONTINUE READING

Related Posts

Industrial sprockets play a pivotal role in enhancing productivity and performance across a spectrum of industrial applications. From conveying systems […]

Spline gears are essential components in mechanical engineering, widely used for their ability to transmit torque and provide precise alignment […]

Roller chain couplings are integral components in various industrial applications, facilitating efficient power transmission between shafts. Their economic impact and […]