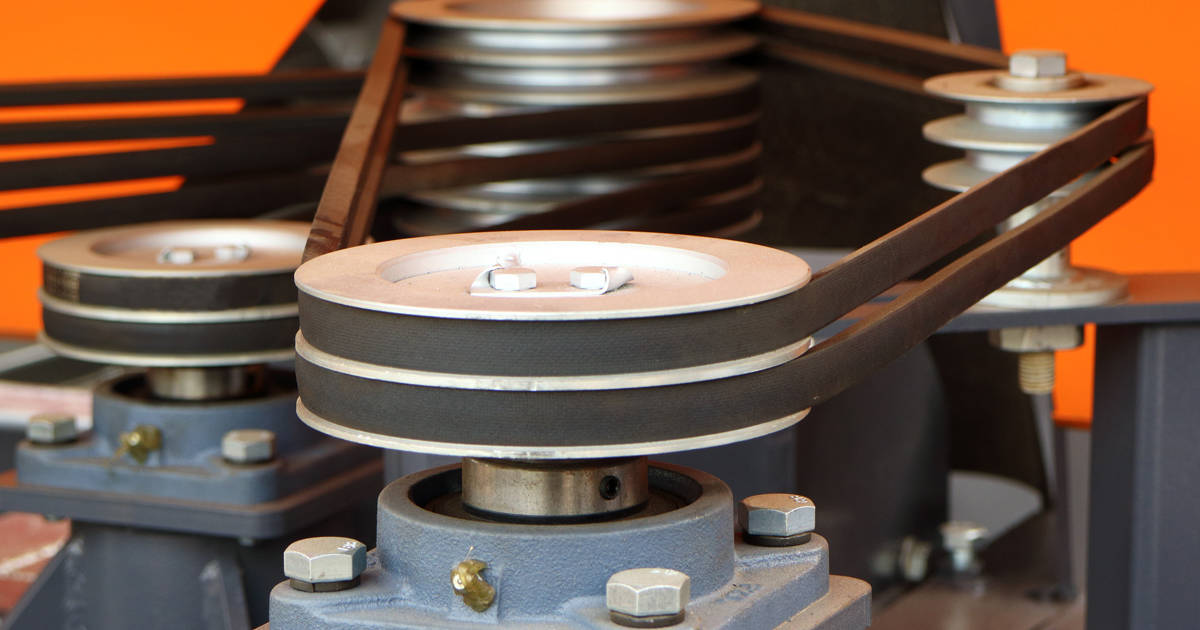

V-pulleys play a vital role in power transmission systems, providing a means to transmit rotational force and maintain belt tension. However, not all V-pulleys are created equal. Industrial V-pulleys and ordinary V-pulleys differ in their construction, design, and performance characteristics. In this article, we will explore the key differences between industrial V-pulleys and ordinary V-pulleys. By understanding these distinctions, engineers and machine operators can make informed decisions when selecting the appropriate V-pulley for their applications, ensuring optimal performance, reliability, and longevity.

Construction and Materials :

Industrial V-pulleys are built to withstand rigorous operating conditions in demanding industrial environments. They are often constructed from high-quality materials such as cast iron, steel, or aluminum. These materials provide superior strength, durability, and resistance to wear and corrosion. On the other hand, ordinary V-pulleys are typically made from lighter materials like plastic or lower-grade metals, making them suitable for lighter-duty applications.

Load Capacity and Power Transmission :

Industrial V-pulleys are designed to handle high loads and transmit substantial power. They feature robust construction and wider belt contact surfaces, ensuring efficient power transmission and reduced belt slippage even under heavy loads. In contrast, ordinary V-pulleys have lower load capacities and are suitable for lighter applications where power transmission requirements are less demanding.

Precision and Performance :

Industrial V-pulleys are manufactured with precision and strict tolerances to ensure accurate belt tracking and alignment. They undergo rigorous quality control processes to maintain consistent dimensions and minimize vibration and noise during operation. Ordinary V-pulleys may have looser tolerances, resulting in potential belt alignment issues and increased wear over time.

Belt Compatibility and Versatility :

Industrial V-pulleys are designed to accommodate a wide range of belt sizes and types. They offer flexibility in terms of belt width, profile, and tooth pitch, allowing for customized configurations based on specific application requirements. Ordinary V-pulleys, on the other hand, may have limited compatibility options and are generally used with standard belts in more basic applications.

Longevity and Maintenance :

Due to their robust construction and high-quality materials, industrial V-pulleys tend to have a longer service life and require less frequent maintenance. They can withstand heavy usage, resist wear, and operate reliably in challenging environments. Ordinary V-pulleys may require more frequent inspections and replacements due to their lighter construction and lower-grade materials.

Cost Considerations :

Industrial V-pulleys, with their enhanced features and durability, typically come at a higher price point compared to ordinary V-pulleys. However, the investment in industrial V-pulleys is justified by their superior performance, extended lifespan, and reduced downtime, leading to long-term cost savings and improved operational efficiency.

Conclusion :

The differences between industrial V-pulleys and ordinary V-pulleys lie in their construction, materials, load capacity, precision, belt compatibility, longevity, and overall performance. Industrial V-pulleys are engineered to meet the demands of heavy-duty industrial applications, offering superior strength, durability, and reliable power transmission. Ordinary V-pulleys, on the other hand, serve well in lighter-duty and less demanding scenarios. When selecting V-pulleys, it is crucial to assess the specific requirements of the application and make an informed decision based on factors such as load capacity, precision, belt compatibility, and long-term cost considerations.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]