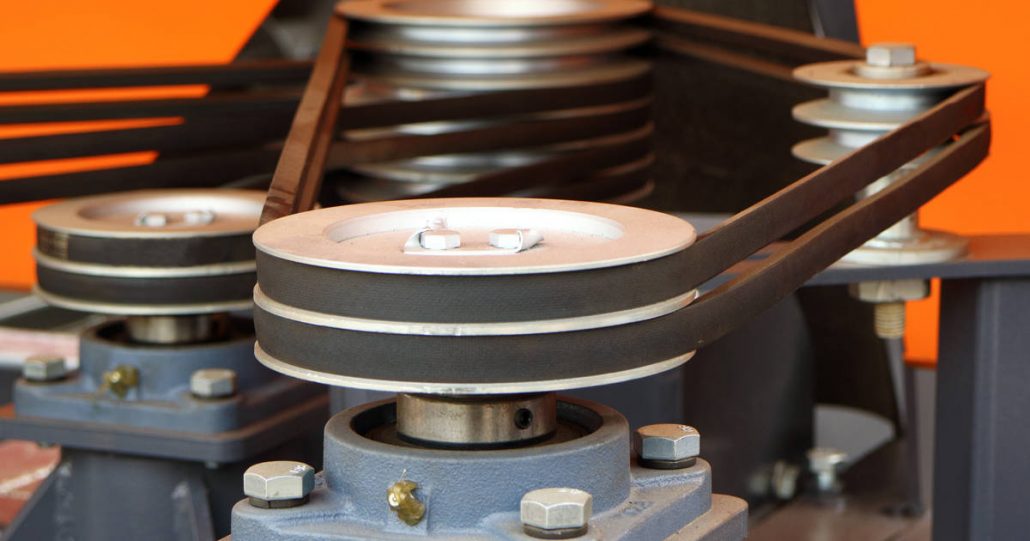

A cogged V-belt pulley is a type of pulley that is designed to work with a cogged or notched V-belt, also known as a synchronous belt. Cogged V-belts have teeth or cogs on the inner surface of the belt that mesh with corresponding teeth on the pulley, providing a positive engagement and ensuring precise power transmission.

Cogged V-belt pulleys are typically made of cast iron or steel and have a series of grooves or teeth that match the profile of the cogged V-belt. The teeth on the pulley mesh with the teeth on the belt, creating a positive engagement that reduces slippage and helps to maintain constant speed and torque.

One of the advantages of using a cogged V-belt pulley is that it can provide higher power transmission capabilities than a standard V-belt pulley. This is because the positive engagement between the teeth on the belt and the pulley helps to transfer more power without slipping or losing efficiency.

Cogged V-belt pulleys are commonly used in a variety of applications, including industrial machinery, automotive engines, and agricultural equipment. They are available in a range of sizes and configurations to accommodate different belt widths and power requirements.

Overall, cogged V-belt pulleys are a reliable and efficient way to transfer power from a motor or engine to a machine or piece of equipment, providing high power transmission capabilities and reducing the risk of slippage or misalignment.

What should be paid attention to when purchasing cogged v belt pulley?

When purchasing a cogged V-belt pulley, there are several key factors that should be considered to ensure that the pulley is the right fit for your application and will provide reliable and efficient power transmission. Some important things to pay attention to when purchasing a cogged V-belt pulley include:

- Belt compatibility: Cogged V-belt pulleys are designed to work with cogged or notched V-belts, so it is important to ensure that the pulley you select is compatible with the belt you plan to use. Check the belt width, pitch, and tooth profile to ensure that they match the pulley specifications.

- Power requirements: Consider the amount of power that needs to be transmitted and select a pulley that is capable of handling the required load. Cogged V-belt pulleys are designed to provide higher power transmission capabilities than standard V-belt pulleys, so make sure that the pulley you select is appropriate for your power requirements.

- Material and quality: Look for a high-quality cogged V-belt pulley made from durable materials such as cast iron or steel. A well-made pulley will provide reliable performance and long service life.

- Size and configuration: Select a cogged V-belt pulley that is the right size and configuration for your application. Consider the number of grooves or teeth on the pulley, as well as the overall size and shape, to ensure that it will fit properly and provide optimal power transmission.

- Manufacturer and supplier reputation: Choose a reputable manufacturer or supplier that is known for producing high-quality cogged V-belt pulleys. Read reviews and check the company’s track record to ensure that you are getting a reliable product from a trustworthy source.

By paying attention to these key factors, you can ensure that you select a cogged V-belt pulley that is the right fit for your application and will provide reliable and efficient power transmission.

CONTINUE READING

Related Posts

In mechanical drives, gears are essential for transmitting motion, power, and torque across various applications. Two of the most commonly […]

In the world of industrial machinery, efficiency, precision, and reliability are essential. A key component in achieving these goals is […]

In the world of industrial engineering, precision and innovation are essential to staying competitive and meeting the ever-growing demands of […]